Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 25, 2009 10:45:23 GMT

;D ;D ;D ;D ;D Wondered how long it would be before bigger engines started preying on your mind  If you're going for a bigger engine forget going the Porsche 356/912/914 route as trying to get one of these for reasonable money is nigh on impossible these days. I had a 1679 Super90 engine in my Bug and it hustled but that was back in the day when you could get one for £200.........nowdays add a zero and expect to rebuild!! Forget the Porsche Flat6...too big.... too heavy....too expensive. Pete on here build a highly tuned 1641 adding bigger barrels and pistons plus other goodies to his 1600 block, and on one of his threads reckon the unit cost £3000. I've built my own 1776 importing most of the parts from the USA, (When the £ got you $2+ on the exchanges), and have change from £1100.........power output is 110bhp at the flywheel. However for the same money I could have gone to 1914cc which could yield 130bhp. Not much more but the major benefit is greater low down torque. the benefit of the 1641 is that there's no machining involved to its merely a heads off, barrels off, pistons off and replace. Doing the spanner work yourself and using Mahle pistons and assuming the rest of the engine is good a bog standard 1300 or 1600 motor can be brought up to 1641 for as little as £200...........add in a camshaft, new carbs, high lift rockers and you start moving north from this figure. I had Porsche brakes on my rollerskate.......but you need to be careful as it is easy to overbrake the car...ie too easy to lock everything up on a lightweight car. I have now got Porsche pattern discs up front with Lotus Sunbeam 4-pot callipers fitted and VW412, (Bigger), drums up the back..you need back plates etc....the drums were blanks supplied by Machine7 and drilled for Porsche PCD. It is easy to convert your ball joint front end to disc brakes..........just need to find the parts at the righ price...but before you decide consider what you are going to do front and back because it is an advantage to have the same wheel stud pattern all round. The Porsche suspension up back is a good conversion...there is some bracketry to be welded to the kipper. Try and get the alloy arms......and everything you need from one source if you can. Also get the later version with the 5 stud wheels as this will give you a rear disc brake conversion at the same time. Convert handbrake to hydraulic operation. The conversion is covered in Keith Seume's VW Beetle Performance Handbook. StuM has got the wiring covered for you....wire up as he said and rig up an ignition switch and hopefully she'll fire...make sure you've got some gas in the tank tho'  Regards Chris |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 25, 2009 11:06:33 GMT

Haha i wouldnt say praying on my mind, 1.3 does wonders to your insurance, especially when your 21.

I've wired up as stu said, however no +,-,cb,s? on the coil, only 1 and 15?

I've hooked it up to a small petrol tank, but its still not catching just turning over.

As far as I can see the fuel pump is sucking, until the carb sucks in air, which pushes the petrol back up the tube, and air bubbles travel up the fuel tube to the tank?

No petrol is being sucked from the pump to the carb.

Any ideas.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 25, 2009 12:14:44 GMT

Never heard of 1/15 on a coil but that don't mean anything !

Anyway 15 is the standard for switched +ve os that goes to the ignition (the terminal I couldn't remember)

And 31 is the earth code os that would go to the points/dizzy !

Sounds like you have a problem with the check valves in the lift pump ( maybe a bit of dirt stoping them sealing as it should not be possable to feed back to the pump) but the venturi in the carb should cause fuel to be drawn up out of the float bowl and not force it back down so you may have trouble there as well (but I have never dealt with nikki carbs so someone else may be able to advise better) !

Stu

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 25, 2009 12:34:54 GMT

I've narrowed it down to the fuel pump valve. The circular disk on top of the fuel pump cap (4 screws). Both in and out pipes are clear, but the valve isnt moving/letting petrol pass through. So off I go to get a new one.

Update:

£12.50 for a new one (pump that is). but need to know if i have alternator or dynamo, wasn't sure on the spot, he said best not to chance it as there was a handling fee if not.

3 questions:

(just about to research) How to do tell difference between alt and dyna?

Can I buy just a valve?

Can I get a better price for a pump online?

While im buying bits, what else is it be to replace, plugs, coil?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 25, 2009 15:37:31 GMT

Hi Ben

Firstly you have a dynamo.........its the cylindrical thing mounted horizontally to the right of the carb. IOf you look at your Mum/Dad's car they'll have an alternator, (Shorter cylindrical thing usually mounted on the engine block with blades attached to the pully).....follow the fan belt and you'll find it. The fact that you have a voltage regulator also denotes that you have a dynamo.

£12.50 for a pump is okay so long as its branded...there's a lot of Chinese made tosh out there. Hopefully the problem is the pump diaphram, (The disc thing), and you should be able to get one of these from you local V-Dub place or even Halfords. In fact is Big Boyz Toyz not down in your neck of the woods? You probably will get one cheaper online but you have to wait until you receive it in the post. Just to be sure turn the motor over with the pump cover off to make sure that the pump operating lever is moving...this is driven off the camshaft....if its not moving then its an engine strip for you....although you could fit a blanking plate over the fuel pump hole in the crankcase and run with a low pressure electric pump.

As StuM says fuel shouldn't be back flowing to the pump from the carb bnut maybe the floats in the float chamber are seized/jammed

New parts.........Plugs are always a good move as are points, rotor arm, distributor cap and condenser......but at this stage all you want to do is get it running to find out if it has potential or is a dog needing a rebuild. Coils can be tempremental with age so a new one is also a good buy.......blue Bosch sports coil with a ballast resistor is the first upgrade from stock...should give you change from £20. I take it you have doen a spark test at the plugs? I.e. Pull a spark plug and ground it against the crankcase to give a good earth and turn the engine over....should get a healthy spark in the gap between the plug electrodes....do this on all four plugs. If no spark then backtrack from the plug back.....plug to plug leads to dizzy cap to rotor arm to points and so on............if you get a healthy spark then the coil is okay.

Lastly......SAFETY FIRST...watch for sparks near petrol and when you ground the plug and turn the engine over hold the plug to the earth with a pair of insulated pliers....you'll get a shock if you do it with bare hands.......

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 25, 2009 15:39:04 GMT

The 944 rear conversion takes your swing axle to an independent rear in a single step. I have the alloy A arms and have the conversion brackets, currently tacked in place on my chassis but about to come off. The advantages are better handling and less unsprung weight with a side advantage of disk brakes on the rear. The handbrake acts on the inside of the hub and is very well contained. I think that the hubs are 5 stud pattern but am not 100% sure. The conversion is quite easy to achieve, you just need to measure very carefully.

jon

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 25, 2009 17:13:37 GMT

Ok brilliant, I will check all the above tomorrow, it started raining so had to put car away  Kept on with the paint stripping today, 80% done the passenger side. Combination of chisel and wire spinner. Found half-a-dozen small reasons not to trust the previous own's work. Floorpan holes filled with what looks like polyfill to be honest, chalky white consistancy, just crumbled out. Pics tomorrow. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 26, 2009 19:27:00 GMT

Pics: Firstly how i've hung the body.  one side attached to wall  Secondly: brought myself a new fuel pump. took bottom off old one and the lower diaphragm was not moving at all. While i was at it i changed the pump rod, old one had lost 4-5mm due to continuing wearing down.  Thirdly: 95% done the passenger side, plus started on driver's. Looks to be a lot of rust from the photo, trust me there's definitely not that much.  Fourthly: Holes holes holes! Tranny tunnel  and floorpan, inbetween lowered area and tranny tunnel.   Tested the spark plugs today, none worked. I'll replace them tomorrow (shop had closed by time i had got back), try again and then we'll see if need to replace coil. Any way to test coil without new plugs, save a trip? Oh and i found a condenser, where should it attach?? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 26, 2009 20:26:52 GMT

I might be wrong but I reckon the previous owner has fitted replacement floor pans each side of the tunnel and the row of holes are the old spot welds which have been chiselled through. H'es then butt welded the pans to the remaining plange. His welding is cr@p. The welding on the tunnel is the worse as the tunnel provides the main structural strength and there is weakness in that area that needs attention as a priority. If you're not a welder yourself get somebody who knows what they're doing to salavge the pan.

Old plugs should still spark....if they're clean and got a good earth. New plugs will not miraculously start banging. You need to trace back from the plug...checking leads, dizzy cap...rotor arm..points etc all the way back to the coil. You can tunr the engine over without the dizzy cap on to see if youre getting any sparking at the points......its process of elimination baring in mind that there might be more than one thing wrong.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 26, 2009 20:29:04 GMT

for the cr@p typing.....its been a long day!! |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 26, 2009 20:37:40 GMT

Ok cool, will have a fun morning of tracing whats going wrong. ;D

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 26, 2009 20:59:52 GMT

Have to agree with Chris on the welding. Totally lacking in penetration and v unsafe.

I did a MIG course at the local college and got an NVQ (I think) but would never consider myself a proper welder but I can still do 10 times better than that. I don't mind patching or a bit of fabrication but I'd always leave structural stuff to an expert.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 7:07:29 GMT

The condenser goes in parallel with the points (one of the books should show exact position) - between the wire to the points and earth, if you lift off the dizzy cap you should see it there !

Look like the floorpan was repaired by the teflon welding company!

Stu

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 13:30:35 GMT

Found out it was a bad coil, thought id replace plugs as they were only quid each.

Went to turn it over and the starter motor gear clicks into place but it doesnt turn. Worried ive done something to it.

It's firmly rusted close, trying adm to open it up. might need to leave it overnight coated in wd40.

EDIT: Totally scrap that, wd40'd it and put it back in, works fine.

BUT the fuel pump is still blowing instead of "sucking". Could it be to do with the choke?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 14:59:17 GMT

Unlikely, try taking the feed to the carb off at the carb end and then turn it over. Fuel should then spurt out the end of the tube that should attach to the carb. If it doesn't then you've either got the feed from the tank on the wrong inlet or the pump isn't being actuated by the engine. If fuel does spurt out (and it should) the fault will be in the carb, stuck floats or something like that.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 15:04:23 GMT

Looking again at the pic of the pump, I notice that the pipe from the tank to the carb and the pipe to the carb at the pump don't seem to be that securely attached. Make sure they are pushed fully on and they should ideally have a clip around them. They could be drawing air in at present and causing some type of back pressure. Also see my last post about testing the pump.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 16:27:52 GMT

Dont worry just me being stupid, turned fuel lines around and it works. No spark yet, changing timing now. New fuel lines too, with crimpers! ;D

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 16:35:12 GMT

Muppet  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 17:35:09 GMT

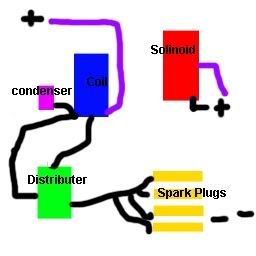

Right, lets try and sort this sparking out. I have fuel, I have starter motor. This is my set up so far (  it's basic and awkward)  Purple wires are shorts from the + battery. Theres a switch in between the ignition coil short as well. There is power to the coil, there is power going through all the spark plug wires. It's a new coil, but when i try to 'test' it, quote from how to keep you VW alive "pull the centre wire out of the dist. cap, hold wire slightly away from engine (ground), turn engine over"....expect spark... but no spark, there's power into coil, the wire is good...but no spark. Is the condensor in the wrong place (connected to - on coil)? Or do i need a new one? I know some distributors have a condensor coming out of them but most of these are vacuum ones, mine isnt. On a similar note the wire coming out of the distributer was already there....but due to it having this Sparkrite thingy, could this wire be wrong? I'll take pics... What's wrong? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 17:52:51 GMT

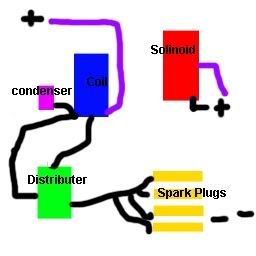

Coil Connections  Under distributer cap  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 17:56:54 GMT

I take it you DO have a rotor arm in there somewhere?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:00:46 GMT

Hi Ben Have you got the green Haynes manual.....check your wiring against the diagram on page 155. ....or get yourself on VZI and ask for Moby on the technical forum...he'll sort it quicker than I can especially as I'm having to go back out now.........  It might be the way you've drawn it out but it's not right...condenser should be off the distributer, so make sure that's right first of all.......... I'll be back about 10ish and can scan the wiring circuit and post it up here if you're no further forward. I have replied to you pm but expect you have the starter motor turning by now? C/ya Chris |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:02:37 GMT

Could you clarify something. You say there is power to the spark plug leads by which I guess you mean the HT leads. Yet you seem to suggest there is no power coming out of the lead from the coil to the dizzy. If this were the case, there would be no power to the spark plug leads (HT's). Also, is your condenser the blue object near the coil?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:06:16 GMT

Okay that's a contactless doo-hicky in the distributor...explains why the condenser is where it is.........these are temremental as well...no easy way to check other than replace with a new one.

Rotor arm essential for sparking at the plugs but you should get a spark at the dizzy end of the HT lead running from the centre of the coil without it in place. Lead firmly in the centre of the coil?

Check battery charge and earth

Where's the lead from the other side of the coil?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:08:43 GMT

yup condensor is blue object near coil. Ok so that should definitely be off of distributer, not sure where to attach this in the distributor, and will probably need a different connection to the one on it at the moment. Would the distributor stop power coming out of coil? Yeh theres a rotor arm attached, and  to clarify...no theres no power coming out of the coil to the dizzy, and thus no power to spark plugs and no spark. but there is definitely power going into coil. ...i thought it might be dodgy leads...so tested them but there's definitely good voltage going through them...thus the lead comment. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:12:55 GMT

Lead firmly in the centre of the coil? .....Check!

Check battery charge and earth?....Double Check!

Where's the lead from the other side of the coil?.....Not connected in the pic, it is there though when i try to start engine.

So the distributor already has a condensor.....so blue thing doesnt need to be there...Ok

But that still doesnt explain why no spark from the coil to dizzy ht lead??

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:18:45 GMT

No the condenser does need to be in the circuit.

The fact that you have the contactless thing means that it has to be mounted elsewhere. Usually it would be mounted to the outside of the dizzy, earthing through the body of the condenser and dizzy, with the wire connecting to the +ive lead of the points...but you dont have points in place.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:34:02 GMT

Right just a quickie as the missus is going potty...but she's not ready herself yet  Connections as follows: Battery negative to earth on floorpan..check good connection. Earth strap from engine/gearbox to floorpan..check good connection. Battery positve to s/motor solonoid..check connection. Solonoid second terminal to ignition switch. S/motor bolted securely to crankcase....earthed through body as is solonoid. Other side of ignition switch to coil. (The unconnected terminal in your pic). Other terminal of coil to dizzy points (Electronic gizmo). Centre of coil to centre of dizzy cap Condensor body to earth...wire to Dizzy points (Electronic gizmo) Dizzy is earthed through monting plate. Plug leads from cap to plugs. If all these are in place and the battery has good charge and connections are good you should get a spark. Condensor is an unknown quantity as is the Electronic gizmo....but if all these are in place then you should get a spark from the end of the coil lead to an earth when you turn the motor over......if not your connections and/or coil are suspect. If either the condensor and electronic gizmo are duff then you wont get a spark at the plugs but you should at the coil. So if you get a spark at the coil but none at the plugs then its a trip to Halfords for points and a condensor...plenty of change from £5 Good luck |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 18:43:16 GMT

Cheers Chris, i was right to get the 12 volt coil??  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2009 19:46:02 GMT

Personally, I think you'd be better to go back to a set of points 'till you get the engine up & running. This would give you a much simpler set up with less to go wrong. As it stands, there are a number of variables that could be causing your problems The trigger wheel could be duff as could the module in the dizzy. For the small cost of a set of points, you could save yourself hours of tinkering & still not getting a result. Bear in mind that any form of electronic ignition that's been lying around unused for a good number of years should be treated with a great deal of suspicion.

|

|

for the cr@p typing.....its been a long day!!

for the cr@p typing.....its been a long day!!