|

|

Post by Peter on Jun 10, 2013 18:53:58 GMT

Sometimes things just come and bit you in the bum. I decided NOT to make a new slimmer version of the centre console and handbrake cover and to recover the old one with my nice new red carbon fibre look vinyl instead, everything went 50% OK as vinyl has a habit of sticking to it's self and like gaffer tape once it sticks to its self, well, knackered.

Went to install the rear section and not enough room between the seat swabs cushions in the gearshift area. fits the tunnel fine but the consul was designed to fit OVER the tunnel not ON it. so need to cut off the handbrake cover which I can still get between the sides of the seats and make a slimmer centre section.

On the good news side I managed to apply some of the vinyl onto backing material and make new gear and handbrake covers as well as re trim the gear knob and handbrake.

Getting there, slowly.

|

|

|

|

Post by Peter on Jun 12, 2013 10:52:28 GMT

Post lady bought me a nice new steering wheel after the old one got ruined by solvent or cockpit cleaner  So BLING, I love it! For only 28 GBP inc post, amazing.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 12, 2013 17:46:08 GMT

that is a nice wheel  I take it its a universal fit or is it specific to the Volkswagen column ? Brett |

|

|

|

Post by Peter on Jun 13, 2013 7:09:31 GMT

Std 6 hole MOMO etc. will fit any standard 6 hole boss. I have a Triumph Dolomite adjustable column (19mm/3/4") with a MOMO boss and Citroen rack and pinion. sunnymew on Ebay have a huge selection of wheels of all types and colours under 30 quid. On the question of bosses there is a profusion of choices. At the moment I have a standard chunky 6 hole Boss bolted onto my column, but drilled and tapped to take the old 5 hole (Grant) wheel as well, so this new one pops straight on the original 6 holes. These bosses need to be vehicle specific, so one would need a VW one to fit the VW shaft. One can get a six hole boss where the centre (hex or splined) welds onto the (usually any 19mm/3/4") shaft and the other bit that the wheel bolts to is quick release, these have the advantage of being shorter, keeping the wheel away from the driver more OR there are adaptors that bolt between the 6 hole boss and the 6 hole wheel in two types, standard 4" and slim 1 1/2" these tend to be cheaper but a standard MOMO type boss plus a standard QR means about 7" of hub  I would like to get the steering wheel further away so I may swap the MOMO boss for a weld on type quick release and save 2" and have QR, difficult to steal a car with no steering wheel or in fact, steal the steering wheel. ;D |

|

|

|

Post by Peter on Jun 16, 2013 11:08:29 GMT

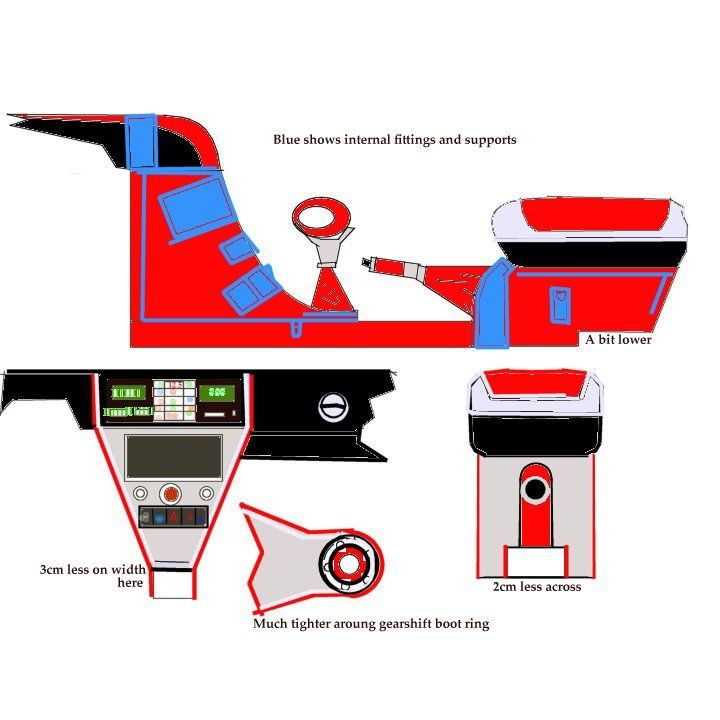

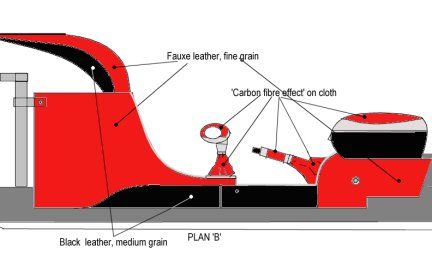

As I said elsewhere, I spent a great day in the 'shed', stripped out all the stuff from the centre console and hand brake cover and after a lot of cardboard templates hit the bin (and a load of crap on the floor) I ended up with a working armrest/handbrake cover. it all fits nicely now, not too worried that the handbrake quadrants rub on the inside as it's not exactly something that is constantly moving. Final adjustment to do as I deliberately made it a bit too long at the back, which can be chopped at will, so I could get the best position over the handbrake but it's pretty close. Next is to make layers of ply to fill in the front leaving spaces for the handbrake boot and the centre section. Stitched up the gearshift and hand brake gaiters, (left my short range specs at home so took half an hour to thread the darn needle in the machine), by sticking some of the red carbon fire look vinyl onto linen to make a tough cloth, also recovered the top of the armrest/box , gear knob and hand brake handle in the same. Scrapped the red 'padded leather look' including the dash bit in favour of a harder more current look with red vinyl directly to the surfaces. Down the centre I have also scrapped the padded black leather cloth, as although it stops the reflections in the screen, it looked crap, so I'm going for an alloy covering again but squares not ribs in an attempt reduce glare, I would love to do machine swirl finish but the wife will not let me dismantle the balcony table for the top, (but ya never knows :wink: ). Next is the centre section and unlike the old one which fitted over the tunnel this one will fit on it so will be narrower by a good 3 cm as it just needs to fit over the sides of the Skoda gear shift. The main centre console will also sit on the centre section instead of over the centre section, saving nearly 5cm on the total width which is where the front of the seat cushion is. The top gear shift will sit on a flat bit with a round finish same as the old one but tight fit. It has to be the same width at the top so the MG speedo fits in but apart from that it's the same layout. Maybe a pop up rearview screen if I go for the Pioneer stereo set up.   Simple sketch showing what I designed.  |

|

|

|

Post by Peter on Jun 23, 2013 15:03:04 GMT

Might have to put things on hold later half of 2013 as I went to the docs last week and he took one look at the x-ray of my remaining knee (Right) and said, "It's a disaster  " by the time I got back home the wife had a had a call with an appointment on 6th August to see the head mechanic at the Malaga's Costa del Sol hospital for a new one,  NOT looking forward to it. Anyone who was at Stones 2006 will vouch I was in a lot of pain from the left replacement at the time that I had 6 weeks before.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 23, 2013 18:05:48 GMT

hope it goes well Peter, my knees are goosed as well but still my original ones ;D, I have osteoarthritis ( not sure about the spelling ) in both of them, I have anti inflammatory's I use whenever I need them and fingers crossed their ok at the moment, I'd heard the knee joint replacement worked well. but sounds like you had a lot of pain with yours ?

Brett

|

|

|

|

Post by Peter on Jun 23, 2013 18:43:27 GMT

Hurt like hell for two/three months and was 2 years before up to speed, just in time for the other one to slow me down again. I had my medial cartilages removed in 1962 (R) and 1972 (L) back in the days when the only treatment for a torn cartilage was to  it out, something they don't do these days unless absolutely necessary is seems. So I developed arthritis in both knees. Doctor wanted to replace the right knee back in 2006 but as I was booked to be with TEAC at Stoneleigh that year I had to drive an automatic and needed my right leg, so they did the left one first instead, now it's overtime for the right one to be done. |

|

|

|

Post by Peter on Jun 30, 2013 20:04:31 GMT

Post lady has been and more stuff for Ukhozi. Red faux leather for trimming, matches the seats and new wheel better. Weld on quick release steering wheel hub., just need to cut end off Triumph shaft and drill 19mm and weld in new end piece. that's all.   82 on Ebay but 26 to me (new) bargain! ;D Pair of rear dampers for Corsa, another thing to keep me way from Ukhozi. Android TV media box as we are loosing our UK TV channels down here soon due to the new satellite. Not as easy as they say to watch TV anywhere, only ONE app found so far that is any good and not just a link to You Tube, Filmon, works. ;D Having fitted new rubbers to the rear of the Corsa and now new rear dampers, (I want fronts too dear", back to Ebay  ), Anette then informs me there is a rattle from the middle underside, so F1 or no F! I get out and get under and the middle box rubbers are shot, so swap with the new rear ones which I can change in a minuet, and reposition the centre box and rear pipe I then need to move the silencer back 2" to clear the axle, any way, all done, missed 35 laps of F!  and absolutely minging, had a few looks in the supermarket on the way home to get her some softener.  . Tomorrow, all being well, I WILL get to the workshop, watch this space! |

|

|

|

Post by Peter on Jul 3, 2013 15:41:00 GMT

Gone and bin an' done it!  Chopped off the Triumph end  Old and new  This  is fitted to this  so I had better think of something, I tried welding but it broke off after a couple hits with the testing tool, 2lb hammer, Maybe a M10 x100mm allen bolt with keys cut in the surfaces like a Mercedes A-class. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 3, 2013 17:00:42 GMT

Picture of your car in Kitcar today Peter

|

|

|

|

Post by Peter on Jul 3, 2013 21:04:17 GMT

|

|

|

|

Post by trike on Jul 5, 2013 19:44:12 GMT

Hmmm....Butt welding the stub to the shaft is probably not a good idea.If you could chamfer the ends to get a good depth of weld its possible,but keeping it straight ain't gonna be easy,and having the wheel come of at speed isn't fun (been there,done that)  Any chance of removing the inner shaft,easy enough to turn up in a lathe and make up a sleeve to join the parts,possibly cross pinned as well. |

|

|

|

Post by Peter on Jul 5, 2013 23:47:52 GMT

Betterer that that, I managed to blag the only HT M10 x 100 Allen bolt in Marbella,  I removed the shaft, should have done that in the first place.  Filled in the OFF CENTRE hole I drilled in-situ by heating up the shaft and then smashing inserting a bit of 8mm bar in, so it welded together when it cooled, I then spun the shaft and got a centre with a felt tip and drilled to 8.5mm and I am about to open to correct tapping size and put the 12mm x1.25 thread in, I will the cut a slot on the column through the hole and remove the sides from the face of the stub creating a keyed surface, I will then bolt the bugger together, it's going nowhere! All I have to do then is reassemble the whole thing. Also managed to get more done on the centre console, main support section forward from the gear shift which mates to the rear section. Also drilled and wired the sump plate.  |

|

|

|

Post by E.O.C. Administrator on Jul 9, 2013 10:29:56 GMT

In the meantime wife's Corsa grew a pair of front dampers, helped a lot as she is bonkers in that car, just had to pay 26€ for spring compressors I though I had but can't find, I think my step-son still has them in his BMW, kids,  |

|

|

|

Post by Peter on Jul 11, 2013 10:09:40 GMT

Anyway, tapped out with my nice new set of M12 taps and once that was done cut a slot in the slug and corresponding steps on the shaft and bolted the two together, checked for alignment and adjusted the fit until it was central and true at this stage I tested it, Wallop! All good, but then welded it anyway, ground out crap bits and welded it and cleaned it up, then beat the crap out of the Allen bolt head, didn't budge, crack or bend, job done. Just need to make a black disc to cover the end of the cover, looking at coffee tin lids etc. or maybe a 4mm ply disc with grained faux leather covering to match the covers. All trued and welded up.  Wheel on   Also managed to redesign the centre console, again, trying for a more 'organic' flow to the main section so extending the main lower support section under the main part and curving the overlay of the main part over the support in black, main in red and hand brake in red all with a 'diamond cut' alloy centre. Just need more time!  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 11, 2013 17:42:33 GMT

looking good Peter  just out of interest, was doing some random googling and found that the Nova moulds are now owned by an Indian company ... and apparently their about to release what basically is an Electric Nova .... here the website www.supernovaev.com/Brett |

|

|

|

Post by Peter on Jul 12, 2013 10:04:37 GMT

It's Hyper Text transfer protocole colon, slash, slash supernovaev.com no www.duno why but can't type in the letters ![frown2[1]](//storage.proboards.com/658221/images/4RoFPGAE9cs9iByWQb34.gif) It has been more than a decade since Shashi Vyas disappeared off the car scene, leaving a lot of broken promises in his wake.  This guy is a dreamer, has been trying for years to get state and privet funding (20.000.000,00 really  !!!) for this project and it really is a no hoper. too expensive for the very limited Indian market (not to mention the roads) and too expensive to ship to Europe. I did make enquires and it would cost over £3,0000 shipping plus import duty and taxes. A half decent LI-Ion battery pack for say a Nissan leaf or Citroen is about £15,000. (that's why you have to lease the batteries on a five year lease at £186 a month, they don't tell you that bit do they?) and a bunch of 10+ deep discharge lead acid batteries (120v as stated to be used), at £150 a pop would be expensive too. Due to the none opening side windows it would fail IVA as well. The cars on the site are older model Nova's, yellow one has the MkI nostrils, the blue one even has the Fiat Coupe head lights and a UK Q plate, both bought with the moulds we think and shipped, untouched, to India! They say a "new chassis" is designed but I have found no evidence that one has ever been made or in fact any moulds yet. The USA market is already supplied by well established company, Stirling Sports Cars LLC with a tubular chassis option for transvers and in-line mid mounted engines. The Noreca from Malaysia (http://norecasportscar.com/index.html )is a MUCH better car all round and cheaper but sadly VW only at the moment and that $6.500,00. This modernised Nova is nice, the F40 spoiler is a bit 'Marmite', but the new lights and rear end is nicer. The current model (and possibly only one taken from the new moulds.) was for a VW chassis which is not a real option these days as a pre-1302 donor VW beetle would be worth too much as a beetle. This car needs to be made in Europe, Spain would welcome it and chuck funds at it as long as it made at least ten jobs.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 12, 2013 18:00:16 GMT

interesting  wasn't aware of this, mind you I wasn't looking ... the indian website mentions a may 2013 release .. but as you say no electric car is cheap, add shipping and its an expensive car ..... wonder what would have happened if a major manufacturer had decided to make something like an Eagle or a Nova as a niche model, they've done it before and managed to shift a few .. the idea of using an existing platform with a new body on top is nothing new  Brett |

|

|

|

Post by Peter on Jul 12, 2013 18:52:44 GMT

Like Opel Tigra, Skoda Rapide, of old and Chrysler Crossfire etc. or do you mean exotic sports cars.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 12, 2013 21:52:13 GMT

quality cars all of them lol ... ok those are examples of how not to do it  |

|

|

|

Post by Peter on Jul 13, 2013 11:46:51 GMT

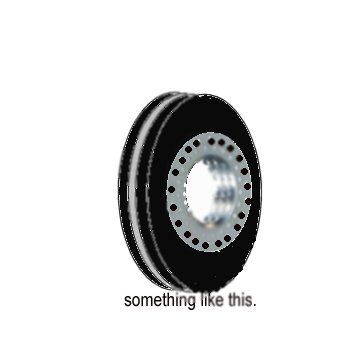

I have got around the problem of the gaping hole around the shaft, I found a sheet of 15mm plastic so cutting a disc with a groove around it is easy, cover in black and trim the centre with a sink strainer with the centre cut out, clamp between the two halves of the cover and jobs a good 'un. Something like.  |

|

|

|

Post by Peter on Jul 15, 2013 23:05:33 GMT

Sometimes the design actually works out in reality. for a change. Quite pleased with my steering cover filler. Sink strainer, who know?  |

|

|

|

Post by Gary on Jul 16, 2013 19:54:30 GMT

Clever  |

|

|

|

Post by Peter on Jul 23, 2013 10:20:29 GMT

Clever, that's me ![rock[1]](//storage.proboards.com/658221/images/WwlTZGzEzqS029BPkumN.gif) Had a GREAT day in the workshop yesterday. finished the handbrake cover/armrest and made good progress on the main console. As you can see I managed to get the same material for trimming as the seat fabric. not easy, also the faux leather for the console sides and dash and doors panels is a very good match shade wise which as anyone will know is a sod with red, so many shades.  Show display light switches, under car, engine and interior  Arm rest/ hand brake cover     Gear shift boot ready on main part which fits over the rear section above and front base  Main front section taking shape, curved side panels will cover the sides and then the shelves, braces and front panel will be fitted before the alloy facia. The sides will fit to the 'white' part and extend down over the black base once the sides are fixed to the 'white' bit and covered in red they will be fixed to the 'black' bit creating the flowed overlayed effect I want and will be echoed in the door panels.  |

|

|

|

Post by Peter on Jul 24, 2013 16:11:38 GMT

MkII door design. Now the centre part is well on the way I can start on the doors, (and the fog lights, wiring upgrade and dash ends, ho hum,  Attachment Deleted Attachment Deleted |

|

|

|

Post by Peter on Jul 28, 2013 10:55:46 GMT

Just a bit more done before family took over,(17th birthday shopping for niece). Bare shell sat on black covered base Attachment DeletedOne side done, shelves and braces in ready for electrics. Attachment DeletedOther side to do. Cut out base for electrics access and then fix to black base and then trim same as rear section then insert electrics and fit speedo etc,, then I can re-do the dash to match. Although I have made the radio housing a 2 DIN I am still not sure if to use the 6.5" Radio/DVD/TV/AV camera. or the twin Pioneer radio/cassette and CD payer combo with separate FM tuner and CD stack and then a separate 'pop up' 7" screen behind the speedo for the reverse view camera. |

|

|

|

Post by Peter on Jul 29, 2013 23:43:45 GMT

Good day in the 'shed'. Managed to get the main console about done, just a bit of fiddling around the radio housing and maybe a facia to go around it. All finished  Back lit and radio working  rear view with the two LED strips. lots of RCA to connect to amps.  |

|

|

|

Post by trike on Jul 30, 2013 6:48:37 GMT

Very nice...never seen a combined radio/camera system before.

|

|

|

|

Post by Peter on Jul 30, 2013 11:58:40 GMT

RV but it's not, def a copy of a CJ6, can't find it via Google either.

|

|